Flawless production of your hydraulic manifolds

Answers

On what CNC machines does HydroCAM run?

HydroCAM is devolped for all kind off CNC machines with different contols. However, the first licenses that are running now are Mazak with Mazatrol controls.

Does HydroCAM have an internal database to generate the machine code?

HydroCAM uses an internal machining library to generate the machine code. This library will be created by the user so this will give you complete control over the way your manifolds are machined, and your manifolds will be machined with high consistency.

What’s the key difference between HydroCAM and conventional CAM software?

HydroCAM is solely designed to aid the production of Hydraulic manifolds where the complex shapes are internal rather than external. The focus with HydroCAM is on automatic feed and speed reduction for cross-drilling, eccentric holes, and machining of predefined shapes (the specified cavities).

Does HydroCAM support 4- and 5-axis machining centers?

There will be no limitation to the amount of axis for HydroCAM, 3-, 4- and 5-axis machines will be supported. When using a 4-axis machine, HydroCAM will also aid in deciding the clamping order depending on angled holes in the manifold to minimize the amount of re-clamping required.

Is it possible to set-up the tool priority in HydroCAM?

Yes, in the library, the general tool priority can be set-up per tool type, diameter ascending. In the future we also wish to make it possible to change the diameter sorting to descending to accommodate tricky materials like stainless steel. In the library, the general tool priority can be overridden with a set of consecutive operations.

Does HydroCAM include post-processors?

The user interface of HydroCAM will display the machine code in the same language as the machining center it will export to. Everything required to export the machine code is included in HydroCAM. However, as of now, HydroCAM only supports Mazak - Mazatrol machine language.

How does HydroCAM communicate with the machining center?

HydroCAM will export the code to a text file that your machining center should be able to import. The import of the machining code is done outside of HydroCAM.

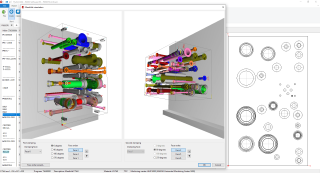

Does HydroCAM include simulation?

HydroCAM has limited simulation functionality, a visual representation of the machining sequence can be viewed, and soon, a rough estimate can be made for machining time and cost. HydroCAM does not simulate to check for spindle collision.

Can the HydroCAM library be used and saved in a shared location?

Yes, the HydroCAM library can be saved anywhere on your network and can be shared among multiple HydroCAM installations. No extra software is required to create a shared library.

Does HydroCAM support engraving?

Yes, HydroCAM can export code for engraving, however, this might need to be customized depending on the machining center and the user’s wishes.

How fast can HydroCAM generate machine code?

If HydroCAM can find all machining operations in its library, it generates the machine code in an instant. Any missing machining operations will trigger a warning, allowing the user to add those missing machining units.

Is there a limit to program length in HydroCAM?

There will be no limitation to the length of the program HydroCAM can generate. It might be that the code will have to be divided in multiple (sub-)programs to accommodate the limits of the machining center.

Do you provide training for using the HydroCAM software?

Yes, One of our training engineers can lead a training session at your location or we will be happy to welcome you at our headquarters in The Netherlands.

Couldn't find your answer?

Contact our support by sending a message through the contact form or send us an e-mail at support@paro.nl.

If you prefer calling, you can also reach our support at +31 251 233 785.